The continuous low-temperature drying equipment can be applied to the dryingreduction of various industrial sludge (papermaking, printing and dyeing, electroplating, chemical industry, pharmaceutical industry, etc.). The water content of the sediment reaches 60% ~ 85% after being dehydrated by screw or filter press. For this part of sludge, the low-temperature drying equipment will do further drying and dehydration, usually reducing the water content to below 30%, and then transporting out or final disposal. This complete set of equipment is developed and designed for the self-reduction of production and waste enterprises. It aims to save freight and disposal costs for users and is suitable for small-scale reduction applications. The equipment only consumes electrical energy, and it is easy to install and use on site.

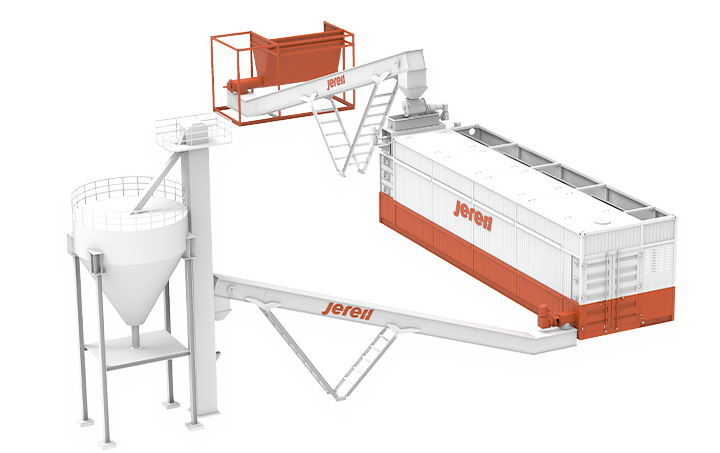

The equipment adopts modular integrated design, covering a small area. It can be assembled quickly, transported conveniently and arranged simply.

The equipment adopts the stainless steel all welded closed design, and the ventilation port is reserved for the exhaust treatment device to ensure that there is no odor overflow on the site.

The lining is made of stainless steel, which is not affected by environment and humidity.

Adopting PLC automatic control system, it can realize fully automatic continuous operation and save a lot of labor cost.

A super filtration system is set on the windward side to avoid dust pollution of the heat pump host.

It adopts three layers plus heavy mesh belt, and precisely designs the conveying track; the external cooling tower balances the cooling capacity and improves the dehumidification efficiency of the equipment.

| Model | Drying standard water removal (kg/24h) |

| TGH3L | 3000 |

| TGH6L | 6000 |

| TGH10L | 10000 |

| TGH20L | 20000 |

| TGH30L | 30000 |

| TGH40L | 40000 |

| TGH50L | 50000 |