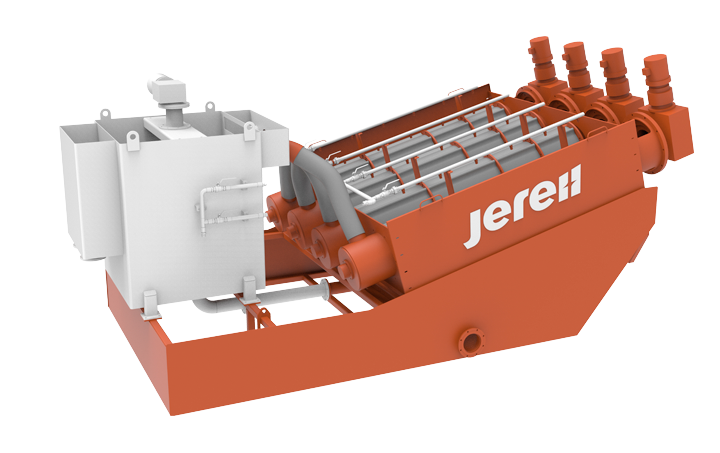

The screw dehydrator is mainly used for sludge treatment in municipal sewage, petroleum refining, brewing leather, printing and dyeing and papermaking, coal beneficiation, biopharmaceuticals, steel pickling, food processing and other industries. During the operation of the equipment, the sludge enters the filter drum from the feed inlet and moves to the discharge outlet under the push of the spiral blade. As the pitch of the spiral blade decreases gradually, the squeeze pressure on the sludge increases gradually. During the pressure maintaining period, the water flows out of the gap between the fixed ring and the floating ring to achieve thepurpose of dehydration. At the same time, the self-cleaning function is realized by the relative movement of the fixed ring and the floating ring to prevent the sludge from blocking the gap, and the dehydrated sludge cake is discharged from the discharge port under the push of the spiral blade. This product is designed and manufactured in strict accordance with "JB/T 12578-2015 screw sludge dewatering machine".

It can be unattended for 24 hours, with short daily maintenance time and simple maintenance operation.

The operation process realizes self-cleaning without blocking and high-pressure water backwashing.

Compared with other dehydration methods, the screw dehydrator is more suitable for the dehydration of viscous oily sludge.

The rotating speed of the screw shaft is about 2~3r/min, with very low power consumption, few faults, little noise and vibration, and safe operation.

It integrates automatic control cabinet, sludge thickening and dewatering body, metering tank and flocculation and mixing tank. It covers a small area and is convenient for maintenance and handling.

| Model | DS Standard DS Standard Handling Capacity(kg/h) | Sludge Treatment Capacity (Approximate)(m³/h) | ||||

| 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | ||

| JRDT201 | 15~30 | 1.5 | 1.0 | 0.8 | 0.7 | 0.6 |

| JRDT202 | 30~60 | 3.0 | 2.0 | 1.6 | 1.3 | 1.2 |

| JRDT203 | 45~90 | 4.5 | 3.0 | 2.4 | 2.0 | 1.8 |

| JRDT251 | 30~60 | 3.0 | 2.0 | 1.6 | 1.3 | 1.2 |

| JRDT252 | 60~120 | 6.0 | 4.0 | 3.2 | 2.7 | 2.4 |

| JRDT253 | 90~180 | 9.0 | 6.0 | 4.8 | 4.0 | 3.6 |

| JRDT301 | 50~100 | 5.0 | 3.3 | 2.7 | 2.2 | 2.0 |

| JRDT302 | 100~200 | 10.0 | 6.7 | 5.3 | 4.4 | 4.0 |

| JRDT303 | 150~300 | 15.0 | 10.0 | 8.0 | 6.7 | 6.0 |

| JRDT304 | 200~400 | 20.0 | 13.3 | 10.7 | 8.9 | 8.0 |

| JRDT351 | 80~160 | 8.0 | 5.3 | 4.3 | 3.6 | 3.2 |

| JRDT352 | 160~320 | 16.0 | 10.7 | 8.5 | 7.1 | 6.4 |

| JRDT353 | 240~480 | 24.0 | 16.0 | 12.8 | 10.7 | 9.6 |

| JRDT354 | 320~640 | 32.0 | 21.3 | 17.1 | 14.2 | 12.8 |